Which Die Casting Machine is the Right Size for Your Project?

Which Size is Right for You?

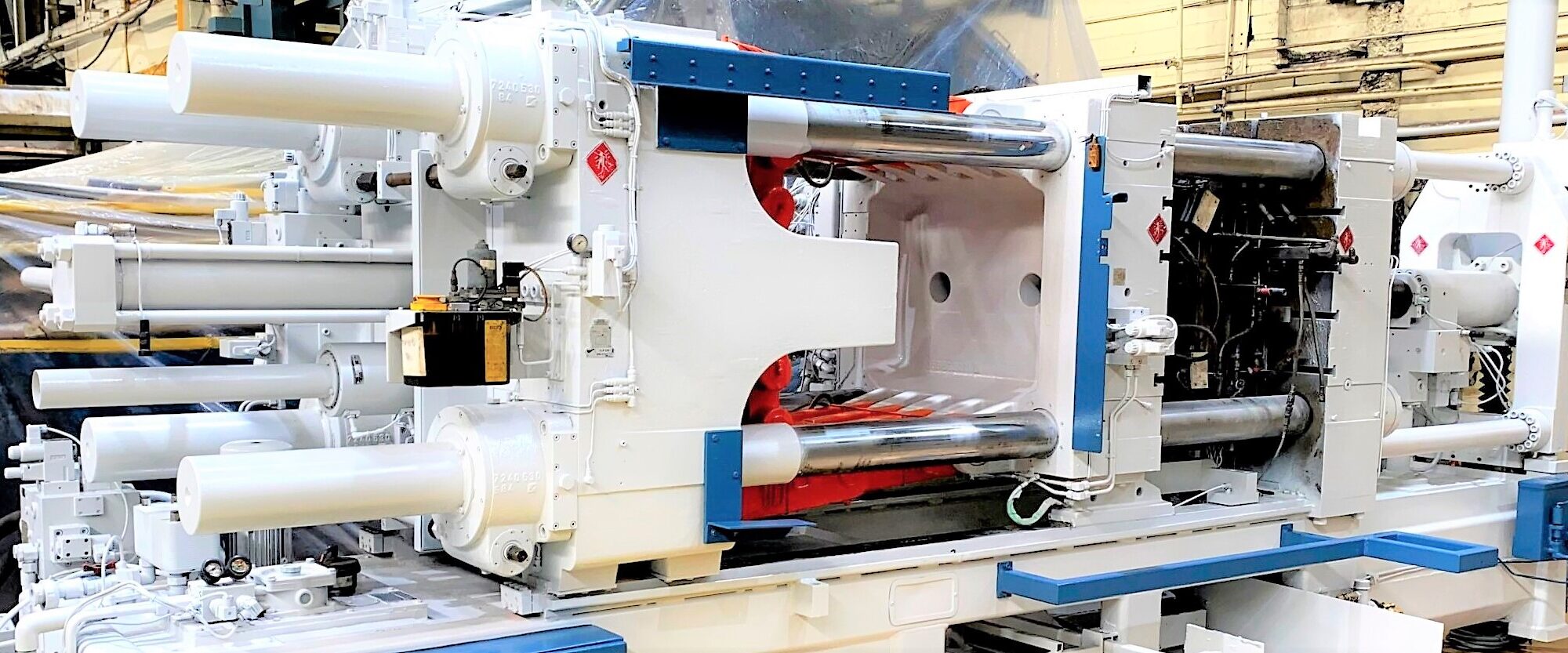

Die casting machines are classified based on locking tonnage. For example, an 800-ton machine has a locking tonnage of 800 tons. Machine specifications vary from brand to brand and even sometimes from year to year. The following chart shows some basic average specifications gathered from several brands over a period of time. Of course, some manufacturers have produced sizes of machines which fall in between the sizes shown below (for example 500 ton) however, the chart is just for basic reference. Each machine size has a flexible shot range (low and high). The shot range can be switched by changing the diameter of the shot sleeve and plunger hence the shot weight below shows a range that is usually possible with each size of machine. A small number of machines larger than 2500 ton have been manufactured, however these are very rare and extremely expensive. Since a die casting machine is selected based on a combination of die size and shot weight, the following tables show some basic guidelines in selecting the correct size of machine for your needs. The “distance between tie bars” is the maximum size of die that will fit into the machine. The die can be single cavity or multiple cavities.

Which is the Right Size for Your Specific Project?

Most die casting projects fall into one of these two categories. This is a simplified explanation, but it covers most projects you will encounter. This table explains how to find the right machine for a specific project.

What is the Estimated Production Output?

This question is a somewhat more complicated question to answer. But there are guidelines which help greatly. Most die casting machine manufacturers (not all) provide “dry cycle” times for their machines. A dry cycle is the amount of time needed for the machine to perform the whole casting process from bringing to end WITHOUT molten metal being added and WITHOUT cooling time of the casting. Generally speaking, the larger the machine the slower the dry cycle time. The reason for this is that larger castings are made on larger machines. The smaller the casting, the less time it needs to solidify and so the “cooling time” (also known as set time in some parts of the world) become less of a factor. With very small castings it is not a factor at all. It all depends on the casting size and weight. It is not possible for die casting machine manufacturers to give figures for “actual cycle” time without sufficient information about each proposed casting and the number of cavities in the die. However, these figures are obtainable from either a die maker or by using “die casting simulation software” and vary greatly from project to project. Such figures are important because they will tell you how much time it would take for the casting(s) to solidify in the cavity(s) after injection and before the machine can open the die and the casting(s) can be removed. So, as you can see, at best, die casting machine manufactures can only provide dry cycle times. To calculate the “actual cycle” time you will need to add “cooling time” to the dry cycle time provided by the machine manufacturer. Here is a simple way to calculate “Estimated Production Output” using only dry cycle times, (but be sure to add “cooling time” to get a “Final Production Output” figure).

Examples:

The following examples are based on a die casting machine

which has a 4 second dry cycle. Keep in mind this is only

“theoretical” and does NOT include “cooling time”.

ESTIMATED PRODUCTION OUTPUT CALCULATION (Dry Cycle) – SINGLE CAVITY DIE

60 sec. (1 min) divided by 4 sec. = 15 castings per minute

15 x 60 minutes = 900 castings per hour

900 x 8 hours = 7,200 castings per 8-hour work day

ESTIMATED PRODUCTION OUTPUT CALCULATION (Dry Cycle) – 4 CAVITY DIE

60 sec. (1 min) divided by 4 sec. = 60 castings per minute

60 x 60 minutes = 3,600 castings per hour

3,600 x 8 hours = 28,800 castings per 8-hour work day