Where Should You Buy a Used Die Casting Machine?

Which is the Right Brand?

There are many manufacturers of die casting machines in the world. However, our many years of experience have shown, over and over again, that the best quality machines are recognized brand names manufacturers and originate from North America, Europe and Japan. As well, do not be too focused on the age of the machine. Due to their construction, and unlike most machines, die casting machines last a very long time. In addition, the technology has not changed too much over the years. Unless you plan to make very high-end castings, most well-made used machines should be sufficient for most applications. There are some good deals to be had slightly older machines.

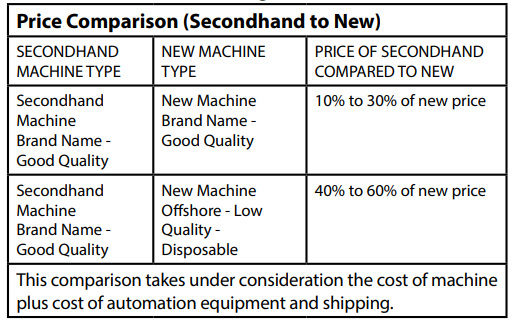

What is a Realistic Budget?

While of course, everyone would like to spend the least amount of money on capital equipment such as a die casting machine, generally speaking, you can use the follow basic guidelines when it comes to comparing prices of new and used machines. The reason for the price range of second-hand machines is the age and the condition.

Where Should You Buy a Used Machine?

When considering the purchase of a used machine, ultimately you have two basic choices.

Buying Privately

The first choice is to buy privately from a die casting company. However, when you think about it, this choice is very often limited, actually more so than you would expect. First of all, by calling from die caster to die caster it is hard to locate the right machine for your needs. Secondly, there are used machinery dealers like my company, in which it is their “business” to call and keep in contact with all die casters on a regular bases and find out if they have machines for sale. For example, our company is in touch with just about every die caster on the planet. When we do find a good machine, we snatch up before it even sees daylight. Therefore, your chances of finding a “good machine” just “phoning around” becomes very remote.

Buying from a Dealer

The second choice you have, is to buy from a die casting machine dealer. There are two types of dealers in the world – stocking and non-stocking. No-stocking dealers accumulate lists of machines available for sale. They offer these for sale to everyone and they usually make about 10% as a selling commission from the owner of the machine. There are 3 problems with this type of business model:

- Non-stocking dealers sell machines that they have not purchased with their own money. As such, they take no responsibility for these machines. They basically “sell and run”.

- Non-stocking dealers have no stock on hand and so they can “disappear” very quickly. They have no big, heavy machines to move which takes time, effort and money.

- Non-stocking dealers offer machines that a stocking dealer like my company already passed up or refused to purchase. When we pass on a machine there must be a very good reason. Non-stocking dealers usually offer the “leftovers” after stocking dealers pick over the good ones.